Types of utility pipe support and its application

ittco » Types of utility pipe support and its application

What are the applications of anchor bolt in any industry?

July 23, 2021

Application of industrial bolts and nuts in industries

August 3, 2021Types of pipe support and its application

Pipe support is a kind of equipment that is commonly used in large utility projects in order to make the utility equipment, to maintain the utilities more easily and to increase their life span. Pipe support is made by different companies and they are supplied to market in different types. In the following, we will introduce you to different types of utility supports, so that you can correctly identify and purchase the products you need.

Gutter pipe support

Gutters are used to install ventilation pipe holders, wires and cable junction boxes. Gutter design is such that makes it easy and more flexible to use.

Strong utility pipe support

These supports are used for steel structures and for utility pipes and equipment that maintain cables. These types of supports are very useful for improving productivity, saving time and doing less work. We recommend galvanized supports, as you can protect parts that are used in environments with moderate corrosion.

Stainless steel parts are commonly used to protect parts in environments with high corrosion rates. We recommend the use of stainless-steel equipment in such cases.

Pipe clamps and hangers

If quick and easy installation is important to you, the technology used in pipe clamps and hangers will help you to connect pipe hangers and clamps as quickly as possible.

pipe clamps

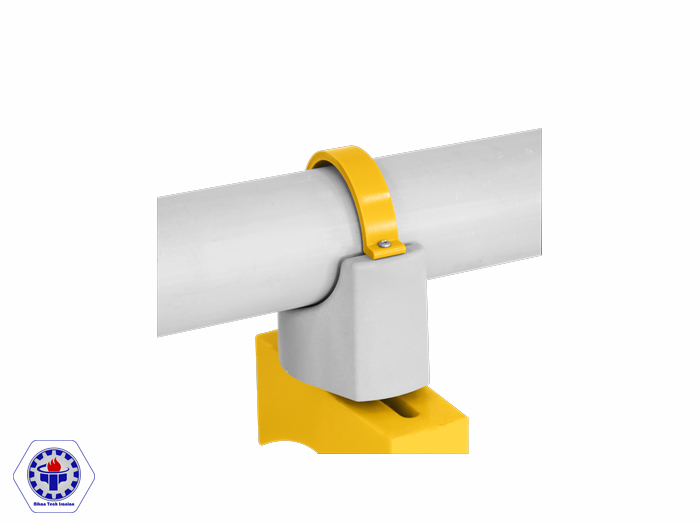

pillar pipe clamp support

These clamps are usually in form of one piece and are very useful for quick installation. All you have to do is to open them and to install. You will not need any nuts if you use the pillar pipe clamps.

Pipe loops

Using pipe loops is suitable when you have different environmental conditions. It is also suitable for pipes made of different materials. generally, it can be said that pipe loops are suitable for various daily tasks.

Support connectors

Steel clamps and hangers and pillar plates need support fasteners to attach them to concrete and building materials. The use of this type of connection is also applicable for steel values and steel beams.

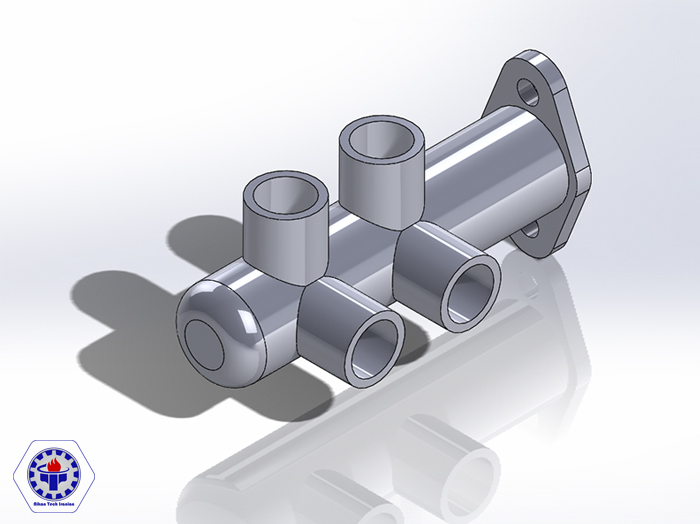

Pipe support equipment

To be able to use hexagonal nuts, bolts, screws, converters and washers, you need equipment for full-threaded radar support systems.

Metal strips of wire and hooks

In the past, in order to be able to properly maintain the pipes and support the pipes, these devices were used in such a way that the hooks were welded by blacksmiths and temporary wires and thin metal strips played their role well. They were connected in such a way that the screw was attached to the cement.

Metal strip wire and hook [/ caption]

Pendant straps or perforated straps

As we explained about metal strips, wires and hooks, you should know that perforated straps and hanging straps were also used to hold the pipes. Perforated straps allow you to adjust the length you want. A perforated strap or hanger strap is usually used when several pipes are to be used as a holder.

Pipe loops

Pipe loops are made of cast iron and have been available to the public since the past, or even from the 19th century. Today, we see that pipe loops are made of steel and the method of connecting them is such that a part of the structure is applied by using anchors and rods if the pipes are large. They are able to support high workloads.

Utility supports usually fall into various categories and can be divided into heavy, medium, and light utility supports. Obviously, heavy utility supports have a higher resistance than light and medium utility pipe supports.

These products are also diverse in terms of the materials and alloys used in them. But parts are usually made of stainless and galvanized steel.

Light utility support

Light loading systems are used for low weight utilities. They can withstand the load of transferring smoke ducts well. They are used for water supply systems of firefighting pipes and electrical and lighting equipment. Among the advantages and features of light loading utility support, we can mention the important points. For example, they are quick and easy to install, like the support of the air conditioning pipe, and do not require welding, paint and drilling, and in the end, the appearance of the work is beautiful. It is possible to reduce the sound when shaking, and the ability to open and close and adjust is one of the advantages of supporting light loading utilities.

It is important to know that their coating is also galvanized and has good corrosion resistance. They cause significant weight loss and are suitable for light loads. Lightweight utility support has a variety of uses and demonstrates its application capabilities in a wide range of areas.

Medium loading utility support system

Among the most widely used types of pipe support, we can mention the support system of medium loading utilities. As the name suggests, these support systems are suitable for relatively heavy and medium loads.

They are designed for fire hoses and flues with different thicknesses and widths. The support system of medium loading utilities is also suitable for air conditioning, and through them, you can use the heating and cooling systems for water transfer, as well as, for electronic and lighting installations.

Among the features and advantages of supporting medium loading facilities, we can mention the ability to build three-dimensional structures and very high strength and stability. Also, these types of supports greatly reduce designing costs. They have multiple uses and are used simultaneously for electricity and utilities. Their coating is also hot and cold galvanized, which makes a beautiful appearance of it. It should be noted that up to 50% supports are effective in reducing weight.

You can use the support of medium loading utilities to strengthen the additional parts of the building, such as, electrical panels. These types of supports for solar panels are also used for cold water pipes and cable trays, air ducts and industrial machinery and equipment, as well as, structural and suspended ceilings.

Heavy load utility pipe support system

If utilities are heavy and we have more special conditions than other utilities, we must use the support system of heavy load utilities. These utilities are very wide and long and are also very thick. They are mostly used in the field of petrochemicals and engine rooms. Fast connection systems are also among their features that will increase the execution speed and have the desired strength.

The features and benefits of this type of utility support are summarized as follows. They are resistant to corrosion and will reduce the weight of the structure up to 50% compared to traditional methods. You will not need paint welding or drilling to install them and they show a very high flexibility.

For getting more useful information about the use of heavy load utility support, we must mention some important points. For instance, these supports are used in risers and are also widely used in oil and gas petrochemical industry and are also suitable for industrial pipes and cable trays.

Today, pipe supports are widely used in construction utilities and provide an opportunity for contractors and engineers to deliver higher quality work and save costs as much as possible.

Modular or prefabricated supports are the best solution used for engineers. As mentioned, utility supports are among the systems that do not require welding and can withstand heavy loads. These systems are receiving more and more attention in various industries.

utility pipe supports

Air conditioning facility support system

In addition to light, medium and heavy utility pipe supports, we can also refer to the support system of air conditioning utilities. These types of supports are selected for utilities and maintenance of the air conditioning system according to the type of the air conditioning system, weight of the utility, estimation of dimensions and other details according to the duct system.

The main uses of air conditioning utility supports are for air conditioning systems and vertical and horizontal air duct supports.

Air conditioning utility supports have different advantages and features, among which we can mention various cases. For example, the fact that they are connected quickly and easily, without welding, paint and any requirement for drilling ultimately makes a beautiful appearance. They can be adjusted, opened and closed and are resistant to corrosion because their coating is galvanized. They cause significant weight loss.

Pipe support price

First of all, we must be aware that the use of quality products is especially important for utility supports, because if these supports need to be replaced or damaged, their cost will increase and the economic justification of the utility project will increase. And causes problems for the industry.

Therefore, it is necessary to fully evaluate the quality of the pipe support and its expenditures, and do not sacrifice the low price for the low quality of the product. It should also be noted that the price of many pipe supports depends on the exchange rate and its fluctuations.

However, if you want to know the exact price of utility pipes support, contact the experts and specialists of Nikan Tak Company.

support

What criteria should we consider when selecting a pipe support system?

Before selecting a pipe support system, determine the expected performance of it correctly. Also, the specifications of the global piping system and the amount of system load and the list of piping lines are among the items that should be considered. Spatial constraints and temperature design of the piping system and compatibility of pipe and support materials are also important. The thickness and insulation of the piping, its compatibility with the environment and the ease of inspection and installation work help you choose the appropriate pipe support system for you. Also, the electrical system and development plans should be considered.