The difference between welding in the gap by the palate or plug welding

ittco » The difference between welding in the gap by the palate or plug welding

Application of industrial bolts and nuts in industries

August 3, 2021

What is a CNC lathe? What information is better about it?

August 8, 2021The difference between welding in the gap by the palate or plug welding

Working with metal is one of the most exciting and practical skills in various industries. Learning this skill requires a lot of ability and a person must practice a lot.to become an expert in this field.

What is welding?

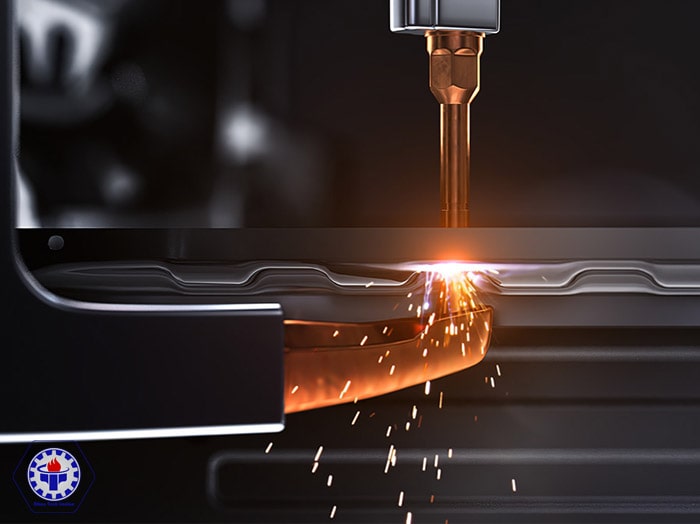

In fact, it can be said that welding is a process performed by humans, in this process, two or more parts of the metal are joined together using pressure and heat, or other changes in the metal, and after cooling, they are not easily separated. Welding is commonly used on metals and thermoplastics. But did you know that this can also be used for wood? Welding is the connection of two or more pieces of metal to each other.

When we turn on the welding machine and start the welding process, we see sparks being thrown, the heat of the metal gradually increases, and the welders can use this to make special and even delicate shapes and products and supply them to market.

What is welding?

Gaining skills in welding

As mentioned at the beginning of the text, you will need a lot of work and practice to get the best results for this precious skill. If you are going to become a professional person in this field, it is better to learn all kinds of welding professional methods with the help and guidance of experts in this industry.

Although learning the basics of this new profession is time consuming, due to the importance of welding in various industries, we recommend that you do not stop learning as much as possible and invest in your skills. You need to be familiar with the whole process from beginning to the end and achieve complete mastery of the previous steps before moving on to the next steps. Paying attention to details will make you an excellent welder and a capable and highly skilled employee.

The most famous welding models

In this section, we want to describe the most famous welding models, such as, back welding, palate welding, corner welding and groove welding to properly understand their differences.

Back welding

If it is not possible to put two parts of metals together, the skill and technique of back welding will help us. In this method, for welding, the backing is used to hold two pieces of metal together. The backing material is usually metal too, but we also see non-metallic types in the market and industry. Sometimes the connection distance between two pieces may be normally large, or it may even be necessary to use a backing for welding due to the lack of access to the back of the piece to maintain the melted material pool.

The reason for naming this type of welding is that the two plates usually connect to the end of each other. Note that the back welding has sections of the corners of the plates in different shapes and sizes. These are called welding backgrounds and will be added to the joints to provide more welding depth.

Corner welding

As the name implies, this model of metal welding is such that it connects only the corners of two adjacent pieces of metals. The angle between the plates in this model is different from welding’s, but it is often 90 degrees and creates a large V to fill the empty space between the metals.

Both sides of the metals will usually be welded for connection in corner welding, but the inner corner will sometimes be left without welding. There are some things to keep in mind when creating a corner welding. It’s like holding the connection point of the corners of two metals very tightly so that they do not come out of the right angle.

Note that in corner welding we are not allowed to apply too much heat to the metals, because if too much heat is applied to the metal, we will see an increase in tension between them. Note that the resistance of the plates depends on the corner welding. Because most metal bonding is done in the corner unless permanent braces are used. Therefore, make sure that you are very careful when welding the corners, so that the result is perfect and faultless.

Corner welding

Slot Welding or buttons

Slot welding is used when welding metals are used in welding, or when we need to fill a gap. To use welding, you do not need any special rules and regulations, you just have to be very careful to weld all parts, so that slot welling can easily cover the empty metal space.

The most practical welding method is button or slot welding and it is used for small and large projects. If you are very careful in slot welding, you will find the best way to eliminate the empty metal spaces.

Groove welding

Groove welding consists of an arrow line, a reference line, and a tail, and are a new method of welding. In this welding method, at the end of the work, we see a groove welding symbol. It is interesting to know that groove welding is one of the second most popular types of welding. A groove welding is a bead that is placed in a groove between two limbs to connect them.

Contrary to many people believe, groove welding symbols can be much more complex than palate welding symbols. Another thing to keep in mind is that groove welding can be combined with palate welding. Groove welding can be one of the most practical welding methods and is widely used.

Groove welding

Concluding remarks

In this article, we tried to introduce you to welding in a brief and general way. Now that you are familiar with the most important types of welding, you need to know that the most practical and popular welding model is slot welding.

Welding is used to fill empty spaces so that no metal is left unused. After slot welding, groove welding is one of the most popular models of welding, which can be considered as a complement to welding. In engineering projects, corner welding is used so that all metals are strongly, safely and basically connected through the corner. Finally, for protective purposes, it is common to use a backing so that the accuracy of the work is not reduced and everything is according to your design and desires.