Introduction of U-bolt & J-Bolt screws and its applications in industry and facilities

ittco » Introduction of U-bolt & J-Bolt screws and its applications in industry and facilities

What is Stud-Bolt and in what industries do we see their use

July 3, 2021

What are the applications of anchor bolt in any industry?

July 23, 2021Introduction of U-bolt & J-Bolt screws

Do you need U-bolt and J-bolt screws in your industry? If you are one of the end users of this type of screws, do not miss reading this article because we have collected important information for you. Nikan Tech Iranian Company offers a variety of industrial and installation U-bolts and J-bolts without any special size restrictions and uses a material with DIN 3570 standard for construction. Buyers can also submit their comments and requests for various or standard coatings so that the company can prepare products in a customized way for customers.

Introduction of U-bolt

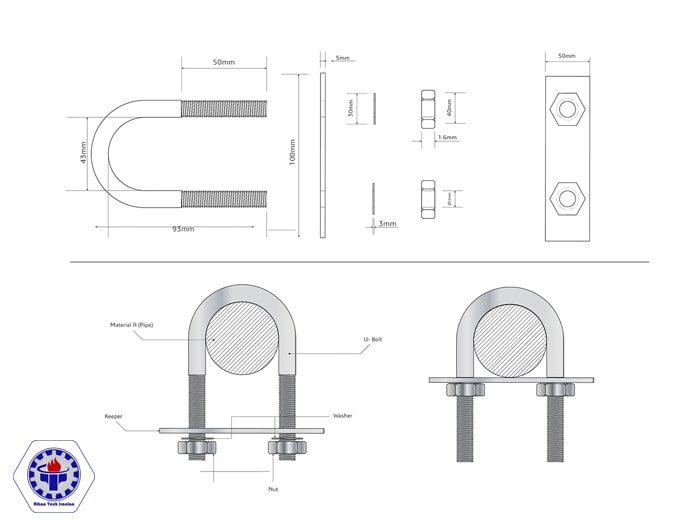

In terms of classification, U-bolts are a type of screw that looks like the English letter U. In fact, this appearance has caused this type of screw to be called by this name. J-Bolt also got the name because of its similarity to the English letter J. The purpose of making U-bolts was primarily to support oil and gas in piping.

Both of these screws are curved and in different types of curves came in different shape, some U-bolts and J-bolts are shorter and some are longer and some are angular. Both of these screws are threaded and each uses them differently.

Did you know that U bolts are named based on the size of the pipe they support? To better understand this point, consider this example. If engineers working in the piping industry ask you for an 8-inch crepe, you should know that this type of screw is needed to fasten an 8-inch pipe. So, it is very important to pay attention to the size of these pages.

Material of all types of bolts and nuts

Material of all types of bolts and nuts

Most types of U-bolt bolts are made of iron, but sometimes steel is also used to make U-bolt bolts. If you are worried about rust or corrosion, we suggest you buy and order hot and cold galvanized type. Try to order a U-bolt bolt, which comes with nickel or zinc, dachromate and… coatings. It is necessary to know that the efficiency of U-bolt is such that it must be used together with the size of components such as nuts, belts and covers. You should know about U-bolts, which are mostly produced and marketed in round, semi-round and cans.

We see the production of U-bolts in different grades. They are used according to the situation. You should also know about 8.8, 10.9, 12.9, which are used in industry and facilities, and if you are going to buy a steel type, make sure that it has grades 304 and 316. U-bolts follow various standards, the most widely used being DIN 3570.

Production and sale of U-bolts and J-bolts

As you know, U-bolts are a kind of bolts and nuts and they are used to connect two parts to each other. Fortunately, U-bolts come in a variety of sizes and grades, and you can purchase or customize them to your liking. Some companies, such as Nikan Tech Iranian Company, are engaged in the production of these products and are directly related to customers and their demands, and offer their products to the market as standard or in the form of your customization. Wire diameter, length, pitch, thread and bending radius, and as mentioned earlier, the type of coating can be customized.

J-bolts are considered as an alternative to I-bolts. The bolt screw opens and closes faster. You should also know about J-bolts, which are generally threaded in the market and do not require a forging process to produce them. J-bolts are curved at the top and the production process takes place after the thread is formed.

The J-Bolt crepe screw is reasonably priced, especially if purchased in bulk. The number of J-Bolt customers is increasing day by day. The reason for this, in addition to the reasonable price, is its very desirable quality. Because the J-Bolt has a forging feature, it is used when a receiver hook is needed.

Industrial and installation bolts

U-bolts are very practical in the industry and we even see home use of this product. It should be noted that industrial U-bolts have differences, the main of which are related to the shape and material of the product. The oil and gas industry are the largest consumer of these types of screws. They are used to support and maintain oil and gas pipelines.

Of course, U-bolt is also used in other industries. For example, if you are working in construction or road construction, you must be familiar with the uses of this screw. It should also be noted that industrial and utility U-bolt screws are also used for boxing.

If you are an electrician or work in the electricity industry with any other title, you have noticed the use of industrial and installation U-bolts. It should also be noted that U-bolt has other uses, such as connecting tow ropes and ropes and connecting various curved parts.

What should we pay attention to when buying a U-bolt?

There are a few things to keep in mind when buying U-bolts. First, pay attention to the material used to make the U-bolt and its cover. Examine the distance between the two end parts of the U-bolt. The two ends of the U-bolt are also known as legs, and some craftsmen use this modification.

Attention the diameter of the U-bolt, the diameter of the U-bolt is related to its inner diameter. Also consider the height of your arms when buying a U-bolt. But as a final point and our recommendation to you is to buy U-bolt in bulk. Because bulk buying will not only reduce your costs but also save you a lot of time.

What should we pay attention to when buying a U-bolt?

Last world and conclusion

In this article, we tried to inform you with the types of U-bolts and J-Bolts used in various industries. We also examined the materials of these two types of screws so that you can buy what you want according to your needs. Finally, we have provided tips on buying this type of screws, the detailed study of which will be your guide for buying U-bolts. Thank you for joining us and we look forward to your constructive feedback.